|  |  Custom Cylindricity System Custom Cylindricity System

ABTech Inc. developed this next generation Cylindricity System for a leading manufacturer of metrology systems. Total lead time from conception to shipment was less than 6 months. The vertical and horizontal linear air bearing slides use ceramic for the rail material for maximum stiffness and thermal stability. Vertical slide straightness is 10µ" over ten inches of travel before software compensation. The Rotary Air Bearing is our standard model AT100 with 2µ" radial and axial accuracy. This metrology platform is designed to work with the customers existing computer and software to provide a well designed, quality finished product. |  |  |  | Turbine Engine Assembly  ABTech, Inc. is working with a leading supplier of turbine engine assembly stages to manufacture, test and ship direct to the end user, these complete systems. The systems utilize ABTech, Inc's precision air bearing rotary tables and integral DC motor drives. ABTech, Inc. is working with a leading supplier of turbine engine assembly stages to manufacture, test and ship direct to the end user, these complete systems. The systems utilize ABTech, Inc's precision air bearing rotary tables and integral DC motor drives. The system pictured at the front features ABTech's model 2500 Heavy Duty Air Bearing Rotary Table. Radial/axial accuracy is ±2.5µ"(±0.063µm) and the load capacity is 2,500lbs(1,134Kg). The system at the back is a model AT300/300-A5-M300V and has a load capacity of 1,000lbs(454Kg). |  |  |  |  Diamond Tool Lapp Machine Diamond Tool Lapp Machine

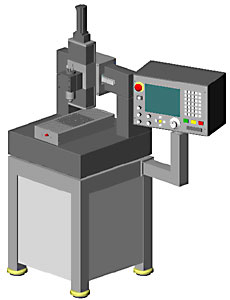

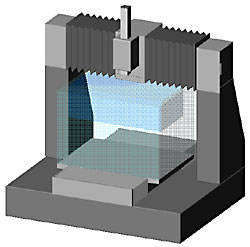

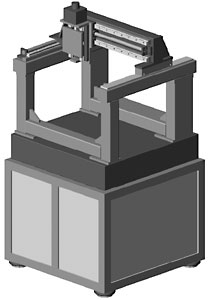

ABTech combined our standard WHS-180 work holding air bearing spindle with a natural granite base and passive air vibration isolation stand, Baladyne™ Automatic Balancer and control electronics to provide a complete turnkey system for re-lapping single point diamond tools |  |  |  | 3-Axis Micro-Drilling Machine & Programmable CNC Controller  ABTech, Inc. proposal #Q577-3 is for this High Precision 3-Axis Micro-Drilling machine complete with programmable CNC controller. This proposed design is for a specific O.E.M. client who fabricates high performance epoxy probe cards and other related accessories for the semi-conductor industry. ABTech, Inc. proposal #Q577-3 is for this High Precision 3-Axis Micro-Drilling machine complete with programmable CNC controller. This proposed design is for a specific O.E.M. client who fabricates high performance epoxy probe cards and other related accessories for the semi-conductor industry. The system uses linear motor driven fully constrained air bearing slides for the X and Y axes. The Z axis is a high precision crossroller mechanical slide driven by a dc brushless servo and zero backlash precision ball screw. The machine base is made up of a natural granite bed, bridge risers and X axis bridge rail supported on a rigid fabricated steel frame complete with passive air vibration isolation. The spindle is a high speed cartridge type capable of 60,000 rpm and can accommodate micro-drill bits from 0.005" to 0.1" in diameter. The controller is a PC based system, Pentium 4 processor and 20GB hard drive. The system features standard CNC G-code programming as well as other standard programming and operating features. |  |  |  | 3-Axis CMM/Vision Inspection System with Computer Control  ABTech's wide product base and extensive experience in design and fabrication of precision motion systems is attractive to companies looking for custom machine development. This proposal design was developed for a client in need of a high precision 3-axis CMM/Vision system. Accuracy requirements prevented the customer from using commercially available systems. ABTech's wide product base and extensive experience in design and fabrication of precision motion systems is attractive to companies looking for custom machine development. This proposal design was developed for a client in need of a high precision 3-axis CMM/Vision system. Accuracy requirements prevented the customer from using commercially available systems. This system is offered complete with full CNC controls, Metronics Corporations CMM/Vision systems software and touch probe. The motion system platform is constructed on a natural granite base and utilizes precision air bearings slides on all 3 axes. The X and Y axis air bearings utilize natural granite rails while the Z axis uses a precision ceramic beam to support the optics and touch probe device. The controls and software are Metronics Corporations QC5300 CMM/Vision system featuring programmable lighting, auto focus, zoom control, edge detection, joy stick control, dual 19" flat screen, E-stop, position compensation, Windows platform and data storage capabilities. Optics include Navitar zoom lens, Panasonic video camera, Olympus objectives, cross hair generator and Fostec coaxial Fiber optic illuminator. The touch probe is Renishaws PH6M touch probe and stylus kit. |  |  |  | 3-Axis Gantry Machine Platforms  ABTech, Inc. expands its O.E.M. capabiltites with these 3-axis Gantry Machine Platforms complete with precision mechanical linear bearing guide ways, DC brushless linear motors and optical encoders. ABTech, Inc. expands its O.E.M. capabiltites with these 3-axis Gantry Machine Platforms complete with precision mechanical linear bearing guide ways, DC brushless linear motors and optical encoders. The design consists of a natural granite base platform with rigid fabricated steel upper structure. The open frame configuration shown here is ideal for Hermetic Sealing Systems, Vision Inspection Systems, Pick & Place Systems and Micro-Machining applications to name a few. The large opening facilitates automated part handling systems to enter the work area and for operator access. These Gantry platforms can be integrated into existing or new machines as a complete turnkey system including full CNC controls. |  |  |  |  | Contact Us! For more information on the systems shown above or to discuss your O.E.M. requirements, contact us today! |  |  |  | |  |